Nickel alloy steel pipe 825

Product Description

Product Introduction: Super Austenitic 825 Alloys

In the realm of advanced materials, Super Austenitic 825 Alloy, designated as UNS N08825, stands out due to its exceptional combination of corrosion resistance, high strength, and impressive mechanical properties across a wide temperature range. This alloy is primarily composed of nickel and chromium, offering notable resilience in extreme environments, making it an ideal choice for various industries, including oil and gas, chemical processing, and marine applications.

Chemical Composition

The unique properties of Super Austenitic 825 are attributed to its carefully engineered chemical composition:

- Nickel (Ni): 38.0–46.0%

- Chromium (Cr): 19.5–23.5%

- Iron (Fe): Minimum 22.0%

- Molybdenum (Mo): 2.5–3.5%

- Titanium (Ti): Maximum 0.6–1.2%

- Copper (Cu): 1.5–3.0%

- Cobalt (Co): Not specified

- Carbon (C): Maximum 0.05%

- Other trace elements are controlled meticulously to ensure optimal performance characteristics.

This careful balance of elements allows Alloy 825 to possess superior resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in environments containing chlorides or sulfuric acid.

Physical Properties

When examining the physical properties of Super Austenitic 825 in the annealed condition, particularly at temperatures ranging from -20°F to +100°F, several key characteristics emerge:

-

Strength and Toughness: The alloy exhibits high tensile strength and yield strength, coupled with good ductility, which is critical for applications requiring materials that can withstand stress without fracturing.

-

Corrosion Resistance: Known for its resistance to a variety of corrosive environments, including reducing and oxidizing conditions, Super Austenitic 825 is favored when operating in chemically aggressive media.

-

Cryogenic Properties: Its outstanding toughness at low temperatures, down to -20°F, ensures reliability in cryogenic applications, making it effective for storage and transportation of liquefied gases.

-

High-Temperature Stability: Maintaining its mechanical integrity even at elevated temperatures, Alloy 825 is suitable for applications exposed to heat and requires material stability to prevent degradation.

Applications

Due to its robust physical properties, Super Austenitic 825 is extensively utilized in several critical sectors:

-

Chemical Processing: Frequently employed in the production of chemicals where the presence of aggressive media, such as acids, is unavoidable.

-

Oil and Gas Exploration: Its resistance to corrosion and cracking, even under high pressure and temperature conditions, makes it indispensable in subsea applications and downhole tubing.

-

Marine Environments: The alloy's exceptional resistance to seawater corrosion makes it an ideal option for marine hardware, components in offshore rigs, and shipbuilding.

Industry Standards and Certifications

Alloy 825 is manufactured in accordance with specific industry standards, such as B/SB704 and B/SB705. These standards ensure that the material meets rigorous testing and safety requirements, affirming its reliability in high-stakes environments.

Conclusion

Super Austenitic 825 Alloy, with its versatile chemical composition and superior physical properties, represents a pinnacle in material technology. It not only meets the demands of modern chemistry and engineering but also performs exceptionally in a range of exigent settings from cryogenic to elevated temperatures. For industries seeking reliable, corrosion-resistant materials capable of enduring extreme conditions, Super Austenitic 825 presents an optimal choice — blending innovation with performance in every application.

In summary, when selecting materials for critical applications, it's essential to consider the unique benefits offered by Alloy 825 as a robust solution to meet today’s engineering challenges.

Packing︰ wooden crate with steel frame

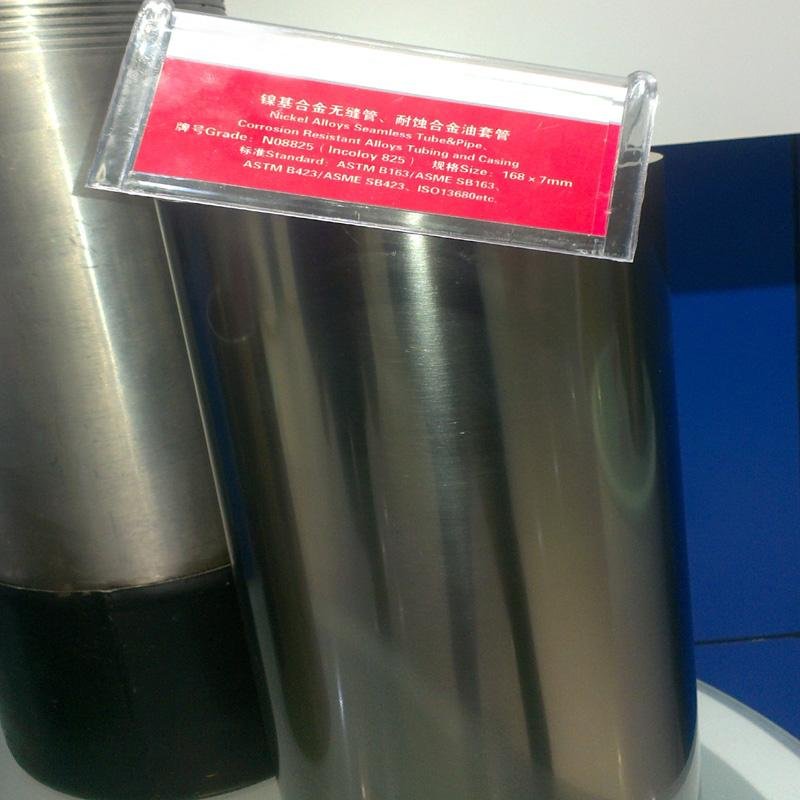

Product Image